It’s a known fact today that if you take preventative action it’s substantially less costly than corrective or remedial action after the fact, in other words, what you have spent to prevent a spill is much cheaper than the clean-up cost down the line, in fact, we use the business case analysis that’s 10 times greater cost to do remedial clean-up fix up work than to do it right at the start. Believe that Katch Kan’s an example of really thinking at the preventative level.

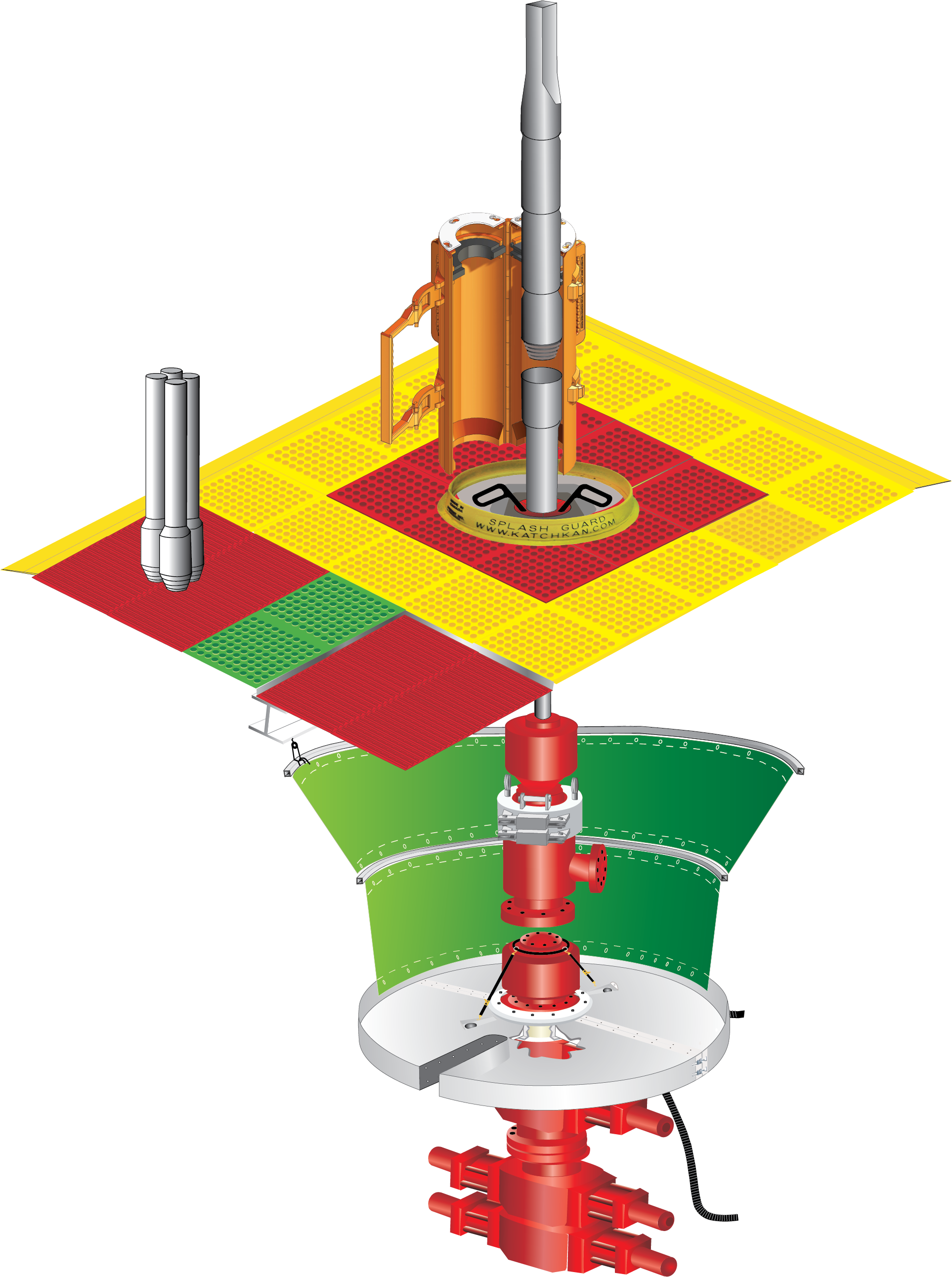

Central Containment System

A system that improves personnel safety captures and redirects lost drilling fluids for recycling or reuse, reducing environmental impact, liabilities, and costs associated with the remediation and reclamation phases.

Kelly Kan™

The Kelly Kan™ seals at the top of any size drill pipe or BHA allows fluid to evacuate down beneath the floor.

Splash Guard

A fully encompassing flexible guard that contains drilling fluid; allowing it to drain through the slips.

Adjustable Containment Enclosure™ (ACE™)

An enclosure device attached to the Low-Profile Load Rated Katch Kan™ that contains fluids escaping through the work floor.

Low-Profile Load Rated Katch Kan™

Collects drilling fluids beneath the rig floor. Seals to API flange, no rig modification. Seals are not susceptible to oil base attacks.

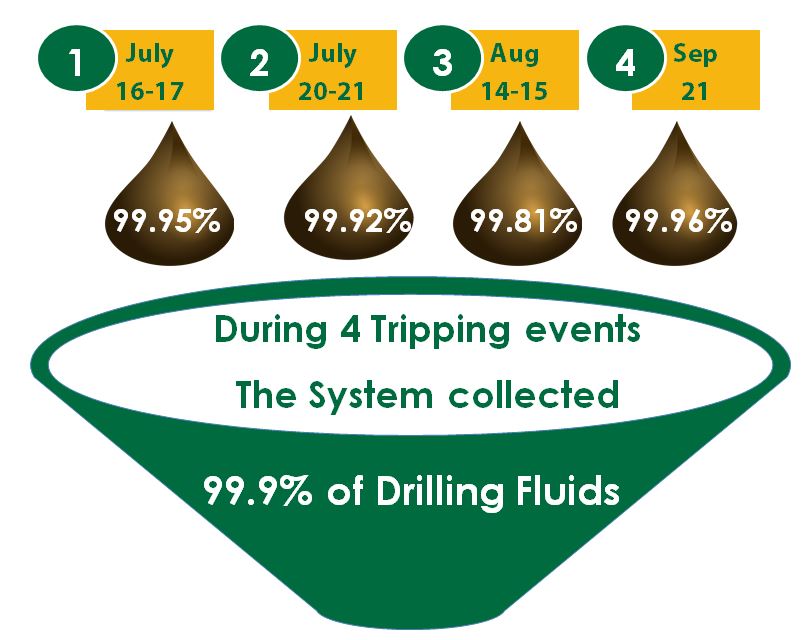

CASE STUDY: VERIFIED 99.9% DRILLING FLUIDS RECOVERY

Based on the data collected during the ETV test, the Katch Kan system collected and retained drilling fluids released from the drill pipe during four tripping events resulting in less than 0.1% of the released fluids escaping to the surrounding environment

CASE STUDY: STAB MAT WITHSTANDS 7 YEARS OF OPERATIONS ON DEEPWATER

In December 2016, a Katch Kan field technician visited the rig and inspected the condition of the matting. The matting had slightly faded in colour, however, the promised performance was still intact. The customer was pleased with the performance and quality and requested to upgrade the rest of the rig floor with Katch Mat.