Stab Mat Overview #

In 2009 a customer in Asia was looking for a product that would have added advantages compared to the traditional wood floor used for racking pipes on the set back area (bird bath).

The customer evaluated and chose our Katch Mat Stab Mat because of the following competitive advantages:

- Channels to drain and redirect fluids while the pipe stands are racked

- Materials to withstand 130 ft triple pipe & drill collar stands

- Nub design prevents pipes from slipping especially during severe weather conditions

In 2009 Katch Kan delivered and installed the Katch MatTM Stab Mat

Results

Katch MatTM Stab Mat withstands 7 years of operation on Deepwater Semi-submersible Rig.

In December 2016, a Katch Kan Field Technician visited the rig and inspected the condition of the matting. The matting had slightly faded in colour, however the promised performance was still intact. The customer was very happy with the performance and quality and requested to upgrade the rest of the rig floor with Katch MatTM.

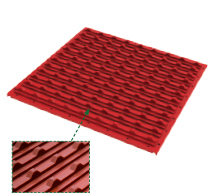

Katch MatTM Stab Mat #

Problem

- Pipe Threading is exposed to wood and metal with the risk of damage

- Run off fluids are not controlled

- Shifting pipes create dangerous work environment

- Wooden surface does not hold up over time

Solution

- Channels allow for fluid to drain and be redirected to drains

- Designed with stability nubs to prevent pipe from shifting or slipping

- Designed to protect pipe threading

- Material used is a heavy-duty polymer designed to withstand 130 ft long triple pipe stands

Results

- Channels allow fluids to drain from the pipe stands and redirect to drains

- Pipe Threads are protected and extend pipe’s working life time

- Pipes are not slipping or shifting during heavy weather conditions

- A durable set back surface lasting 7 years and counting